What's A Hydraulic System & How Does It Work?

페이지 정보

본문

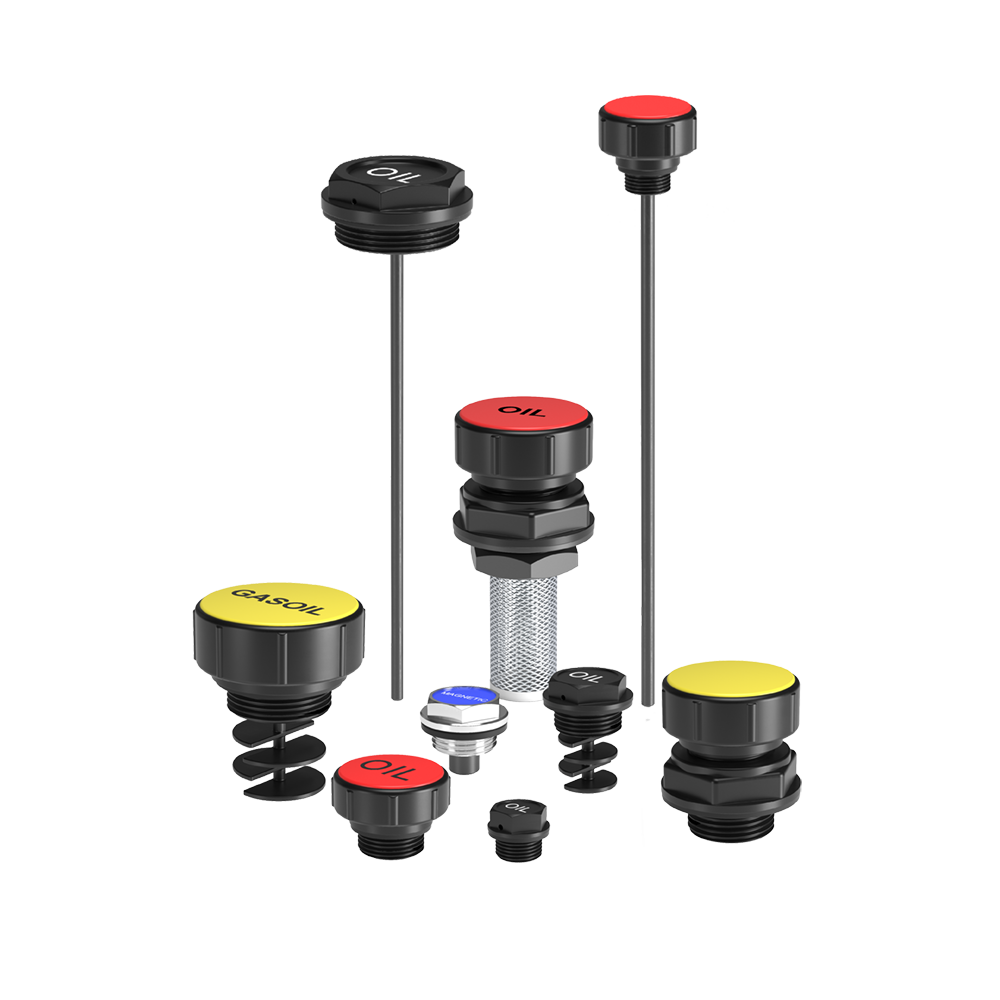

The purpose of a specific hydraulic system could differ, however all hydraulic programs work by way of the same primary idea. Defined merely, hydraulic spare parts programs perform and carry out duties via using a fluid that's pressurized. One other means to place this is the pressurized fluid makes issues work. The ability of liquid fuel in hydraulics is significant and because of this, hydraulic are generally used in heavy gear. In a hydraulic system, pressure, applied to a contained fluid at any level, is transmitted undiminished. That pressurized fluid acts upon every part of the section of a containing vessel and creates pressure or energy. On account of using this power, and depending on how it’s applied, operators can raise heavy hundreds, and exact repetitive duties can be simply finished. Verify you're working within your gear's load limits and producer-beneficial engine working speeds. Regulate restrictors and relief valves precisely as indicated in your owner's guide. 2. The Oil Foams or Overheats. Make sure the oil is clear, full and of the really helpful type. Verify you will have the right reservoir size and cleanliness, and clean or exchange if wanted. Check the oil cooler for proper operation and repair or change it out as needed.

Within the case of a hydraulic machine, you need to convert electrical energy to mechanical energy inside the electric motor, leading to partial waste. Then you need to convert mechanical power into hydraulic energy throughout the pump, leading to partial waste. Then you should convert hydraulic energy again into mechanical vitality at your cylinder or hydraulic motor, leading to partial waste. The internal workings of the hydraulic gear pump. Fluid Leaks: Leaks across the pump housing or seals recommend seal failures or cracks within the pump physique. Irregularities in Fluid: If the hydraulic fluid seems milky or has seen contaminants, it might point out issues like water ingress or internal part put on releasing steel shavings. Erratic Behavior: Any unpredictable conduct, like intermittent drops in stress, suggests attainable points with the pump’s controls or inside parts. Efficient troubleshooting is half the battle in sustaining hydraulic pumps. Common Inspection: Schedule routine visual inspections of the pump and its surroundings. Test for leaks, listen for unusual sounds, and monitor temperature and vibration.

All production finish of line inspections and controls are completed primarily based on the original hydraulic parts specifications and drawings respecting the same match, hardness norms and tolerances as on OEM hydraulic parts. Our Workforce bought many years of experience in conception, manufacturing,inspection and distribution in the sphere of hydraulic pump replacement parts for heavy equipment and tractors. A hydraulic system makes use of a fluid beneath strain to drive machinery or transfer mechanical components. Nearly all aircraft make use of some hydraulically powered elements. In gentle, common aviation aircraft, this might be restricted to offering strain to activate the wheel brakes. In larger and extra advanced aeroplanes, using hydraulically powered parts is much more common. A hydraulic system consists of the hydraulic fluid plus three major mechanical elements.

Hand pumps are extraordinarily easy to make use of. Each hydraulic hand pump has a lever or different actuation handle linked to the pump that, when pulled and pushed, causes the hydraulic liquid within the pump's system to be depressurized or pressurized. This action, within the occasion of a hydraulic machine, offers energy to the units to which the pump is connected. The actuation of a water pump causes the liquid to be pulled from its supply and transferred to another location. All hydraulic hoses have a minimal bend radius; because the identify suggests, that is how far a hose can be bent without damaging the inner tube or reinforcement layer. As a result of fluids consistently attempt to search out the trail of least resistance, they’re making use of strain to the hose’s inner sealings, making an attempt to find a manner out. Power Generation: These motors generate rotational power to energy numerous equipment throughout industries. Driving Machinery: Hydraulic motors energy numerous industrial and cell purposes. They enable pumps, conveyors, cranes, excavators, drilling rigs, and agricultural machinery to carry out work by rotational motion. Versatility in Purposes: They provide adaptability in various purposes. It is due to their capability to generate substantial torque even at low speeds, making them suitable for heavy-duty tasks.

Detents are usually a spring loaded ball (sure, precise ball) that can lock into a groove in the valve spool. There are a few components that don’t match into any specific categories that I would like to share now. Stress gauges are the most typical. They may give the pressure of the road the place they are installed. Remember of the effects of circulate within the system. Centrifugal hydraulic pumps function on a simple principal. When the liquid is made to rotate by an exterior mechanical drive, due to the centrifugal pressure developed, it's thrown away from the central axis. This centrifugal power creates centrifugal head in the liquid and helps it rise to larger levels. Because of the centrifugal action, the liquid is thrown out thereby making a vacuum at the core of the pump. As a consequence, if connected to the liquid reservoir, it's going to suck further liquid into the pump, making it attainable to repeatedly deliver fluid at increased strain. For greater than 60 years the Staffa title has been synonymous with the best at school radial piston hydraulic motors. The Staffa product range has continued to become fastened, variable and high power variations that present high-torque, low-pace management to a variety of purposes. Staffa motors are present in the most arduous marine and industrial purposes equivalent to deck equipment, offshore winches, plastic injection moulding machines and drill rigs. The hydraulically balanced development and Kawasaki’s no-compromise strategy to high quality end in a motor with ranges of reliability unmatched in the market today.

- 이전글What Everybody Must Know about Site Poker 24.10.13

- 다음글9 Things Your Parents Teach You About Bad Anxiety Symptoms 24.10.13

댓글목록

등록된 댓글이 없습니다.